Introduction:

Artificial intelligence (AI) is revolutionizing the manufacturing world by sparking innovation, boosting operational efficiency, and creating a strong competitive edge. Embracing AI doesn’t just streamline processes—it also helps businesses raise productivity and product quality. In today’s tech-driven marketplace, using AI isn’t optional; it’s essential.

AI Market Insights

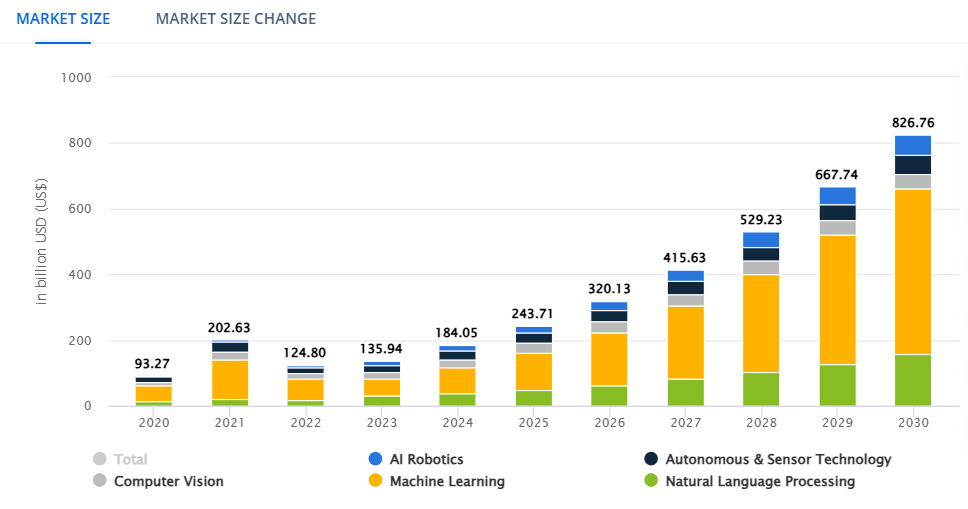

• Growing Demand: According to Statista, the global AI market is projected to reach around $826 billion by 2030—a clear sign of its rapid expansion.

• Cross-Industry Adoption: AI’s broad appeal spans many sectors, yet manufacturing leads in implementing these intelligent solutions.

What to Expect in This Blog

We’ll explore how AI is shaping manufacturing, from use cases to the practical benefits it delivers. You’ll also get a roadmap for smooth AI implementation. By the end, it will be clear that AI is more than just another tool—it’s becoming the backbone of modern manufacturing.

What is AI in the Manufacturing Industry?

Artificial Intelligence (AI) in manufacturing revolves around employing intelligent algorithms and systems to streamline production, elevate quality standards, and control expenses. By imitating human problem-solving and decision-making, AI empowers manufacturers to automate complex tasks and make insightful decisions. Key AI-driven technologies include:

• Machine Learning (ML): Reveals data patterns and continually refines processes.

• Computer Vision: Identifies defects and ensures consistent quality control using advanced image-based analysis.

• Natural Language Processing (NLP): Simplifies human-machine communication, boosting overall efficiency.

• Robotics and Automation: Handles repetitive assignments, enabling faster production and heightened precision. Together, these technologies foster a data-centric, intelligent manufacturing ecosystem that drives higher efficiency and helps businesses maintain a competitive edge.

Benefits of AI in Manufacturing

AI is transforming the manufacturing sector by optimizing processes, enhancing product quality, and promoting sustainability. Its implementation helps companies operate faster, reduce waste, and gain a competitive advantage. Here are some of the leading benefits AI brings to manufacturing:

Boosted Productivity and Efficiency

AI-driven analytics pinpoint production bottlenecks and automate repetitive tasks, significantly cutting down on delays. As a result, manufacturers can streamline workflows and maximize overall productivity.

Higher Quality Products

By using AI-powered automation and computer vision, manufacturers can consistently identify defects and maintain uniform product quality. This level of precision lowers the risk of recalls, improves brand reputation, and keeps customers satisfied.

Cost Savings and Less Waste

Advanced AI tools_detect inefficiencies across production lines and supply chains. Through such insights, organizations can minimize waste, better manage resources, and reduce operating expenses—leading to leaner, more cost-effective operations.

Greater Sustainability

AI supports greener manufacturing by improving energy efficiency and reducing excessive material consumption. Intelligent resource management encourages environmentally responsible practices and helps meet sustainability goals.

11 Key AI Use Cases in Manufacturing

Artificial intelligence is reshaping the manufacturing sector by tackling complex challenges and streamlining processes. From boosting equipment reliability to enhancing worker safety, AI offers a range of solutions that foster innovation and efficiency. Below are 11 prominent ways AI is transforming manufacturing.

- Predictive Maintenance

By utilizing sensors and advanced algorithms, AI enables continuous monitoring of machinery to detect potential failures before they disrupt operations. Scheduling maintenance at precisely the right time lowers expensive downtime and lengthens the lifespan of critical equipment. Incorporating predictive maintenance with the support of AI development services further reduces repair costs and keeps production running smoothly. - Quality Control and Inspection

AI-driven quality control relies on computer vision systems to evaluate products in real time. This technology swiftly identifies defects and irregularities with greater accuracy than human inspectors. The result is consistent product quality, diminished recall rates, and heightened customer satisfaction—all achieved while enhancing overall productivity. - Supply Chain Optimization

AI plays a pivotal role in enhancing supply chain efficiency by delivering more accurate demand forecasts, optimizing logistics routes, and fine-tuning inventory management. Through its analysis of historical trends and current market data, AI offers manufacturers clearer insights into production needs. Additionally, it flags potential supply chain bottlenecks and offers strategies to resolve them, ultimately cutting down delays and expenses. - Generative Design

Generative design taps into AI algorithms to rapidly produce multiple design possibilities based on key constraints like materials, budget, and functionality. This approach accelerates product development, conserves resources, and sparks innovative thinking. With AI’s ability to swiftly generate prototypes, manufacturers can refine ideas faster, significantly shortening the time from concept to market. - Energy Optimization

By monitoring energy usage patterns in real-time, AI systems help minimize waste and boost efficiency. Smart controls can automatically deactivate idle machinery or adjust power consumption to match production demands, leading to meaningful reductions in both costs and environmental impact. Through these automated optimizations, manufacturers can maintain productivity while reducing their carbon footprint. - Production Line Automation

AI-powered automation drives modern production lines by taking over tasks that are repetitive or resource-intensive. Machine learning models fine-tune workflows for faster, more accurate manufacturing. This boosts output, enhances precision, and reduces overall costs, while also enabling easy adaptation to new production needs. - Process Optimization

By analyzing and interpreting manufacturing data, AI uncovers inefficiencies that might otherwise remain hidden. Machine learning tools spot trends and offer recommendations to streamline processes—whether it involves adjusting machine speed or reconfiguring workflows. This continuous improvement approach leads to less downtime, better product quality, and increased savings. - AI-Driven Inventory Management

AI transforms inventory control by tracking stock levels in real-time and triggering automatic restocking. Intelligent systems use sales data and historical trends to predict demand, helping maintain optimal inventory. This reduces the risk of overstock or shortages, leading to smoother operations and higher customer satisfaction. - AI in Safety and Hazard Detection

AI plays a pivotal role in enhancing workplace safety by continuously monitoring environmental conditions and pinpointing potential risks. Rather than waiting for accidents to occur, these advanced systems proactively address hazards, resulting in safer manufacturing operations. They also help companies uphold safety standards and regulations, ultimately minimizing accidents and creating a secure work setting. - AI for Customization and On-Demand Manufacturing

By examining customer preferences in real-time, AI enables manufacturers to efficiently produce customized items. This process not only streamlines custom orders but also illustrates how businesses can leverage AI for on-demand manufacturing, ensuring unique customer needs are met while still maintaining speed and quality. As a result, personalized production becomes more accessible, driving customer satisfaction and innovation. - AI for Workforce Management

In workforce management, AI refines processes by automating shift scheduling and monitoring team performance. Through these insights, organizations can optimize employee allocation for specific tasks and identify strategies to boost productivity. This data-driven approach bolsters employee morale while improving overall efficiency, ensuring that the right people are assigned to the right responsibilities.

How to Implement AI in Manufacturing: A Practical Roadmap

- Evaluate Existing Capabilities

Start by assessing your current systems, workflows, and data infrastructure. Determine if the data you collect is useful for AI applications and whether your workforce is ready for AI-driven changes. Any gaps in technology or data readiness should be addressed early to lay a strong foundation for AI integration. - Define Targeted Use Cases

Identify key areas where AI can provide tangible benefits—predictive maintenance, quality control, and supply chain optimization are common examples. Tie these use cases to broader business objectives so that AI implementations tackle real-world challenges and deliver measurable returns. - Select Appropriate Tools and Technologies

Choose AI platforms and technologies that best align with your technical environment and long-term goals. Options include frameworks like TensorFlow for machine learning, Azure AI for scalable cloud solutions, or IBM Watson for advanced analytics. Ensure compatibility with your existing infrastructure and the ability to scale over time. - Pilot, Refine, and Scale

Begin with a small pilot project to test AI solutions in a controlled setting. Track performance, note areas that need improvement, and adjust your approach as needed. Once the pilot successfully meets its goals, roll out the AI solutions on a larger scale to capture the full benefits across your organization. - Educate and Empower Your Workforce

Provide training resources and hands-on learning opportunities to help employees adopt AI technologies. A well-prepared team can make better use of AI tools, reducing resistance to change and maximizing potential gains for your business. - Continuously Monitor and Improve

Establish a feedback loop to assess AI performance on an ongoing basis. Use data and insights from real-world operations to fine-tune AI models, enhance accuracy, and adapt to evolving business needs. Regular evaluations ensure that your AI strategy remains relevant and effective.

Challenges of AI Adoption in Manufacturing

AI in Manufacturing has the power to transform the industry, but integrating it into existing processes isn’t always straightforward. Businesses must overcome common hurdles to ensure a smooth AI rollout and long-term success. Below are four key challenges:

- Data Silos and Quality

Data fuels AI, yet many manufacturers store information in siloed, legacy systems that don’t communicate well. Low-quality or inconsistent data can also hamper AI effectiveness, producing inaccurate outcomes. To address these issues, companies should invest in data integration tools and prioritize ongoing data cleansing and validation. - High Costs

Implementing AI can be expensive, particularly for small and medium-sized enterprises (SMEs). Upfront expenses include purchasing specialized hardware, software, and hiring skilled professionals. While the long-term benefits often outweigh these initial costs, businesses need to plan carefully for the early financial strain. Exploring scalable AI solutions or seeking grants and subsidies can help ease the burden. - Workforce Resistance

Employees may fear job losses or feel uneasy about automation. Building trust requires transparent communication, inclusive decision-making, and training programs that show how AI can actually enhance—rather than replace—their roles. Framing AI as a productivity tool rather than a job disruptor can go a long way in reducing resistance. - Regulatory Compliance

Finally, AI adoption must mesh with industry regulations and data privacy mandates. From worker safety and handling sensitive information. Failure to meet regulatory standards can lead to legal problems and reputational damage. Collaborating with legal experts and proactively aligning AI systems with all relevant regulations can prevent these issues.

By acknowledging these challenges and implementing thoughtful strategies, manufacturers can pave the way for successful AI integration that drives innovation and growth.

Conclusion

Artificial intelligence has become a transformative force in manufacturing, elevating efficiency, sparking innovation, and promoting sustainability. Whether it’s streamlining predictive maintenance or optimizing supply chains, AI is turning traditional processes into faster, smarter, and more dependable operations. Its potential to completely reshape the industry is indisputable.

For businesses exploring AI, the best strategy is to think big while starting small. Testing AI solutions on a limited scale helps control risks and highlights tangible benefits. As these early successes build confidence, expanding AI throughout the organization becomes both smoother and more impactful.

In a rapidly evolving marketplace, integrating AI has shifted from a competitive advantage to a necessity. Partnering with experienced AI development firms allows businesses to tailor AI solutions to meet their exact requirements. By embracing AI today, manufacturers position themselves as industry frontrunners, ready to address future challenges with innovation and assurance.